Direct Dyes

Direct Dyes

Direct dyes are mainly disazo and polyazo dyes. These dye molecules are relatively long, exhibiting high affinity to fibers, excellent directness towards the fiber, this type of dyes is called direct dyes. The biggest feature of direct dyes is their directness. For example, direct dyes dissolve directly in water without the need for acids, alkalis, oxidizing agents, or reducing agents; They bind directly to cellulose fibers with the aid of only inorganic salts and temperature; Direct dyes are used for dyeing cellulose fibers and can be dyed directly without the need for mordants, other oxidation and reduction effects, etc.

Direct dyes are primarily used for dyeing and printing cotton, viscose, silk, and linen fibers, and can also be used for nylon and wool. When dyeing cellulose fibers, neutral or weak alkaline dye baths are typically used, while for protein fibers, neutral or weak acidic baths are preferred. Direct dyes are also widely utilized in coloring leather, paper, and other materials.

The synthesis process of direct dyes is simple, they come in a wide range of colors, and are convenient to use, making them cost-effective. So they find extensive applications in the dyeing and printing of cellulose and protein fibers. However, direct dyes generally exhibit poor resistance to high temperatures, washing, and light. Those with light fastness ratings of 5 or above are often referred to as direct fast dyes (known as direct L-type dyes).

Application of Direct Dyes

1. Exhaust dyeing

1.1 recipe of dyeing bath

| Dyeing method | Weak alkli | Neutral |

| Dye,% (owf) | x | y |

| Na2CO3,% (owf) | 1 ~ 2 | - |

| Na2SO4,% (owf) | 10 ~ 30 | 10 ~ 30 |

1.2 Dyeing procedure

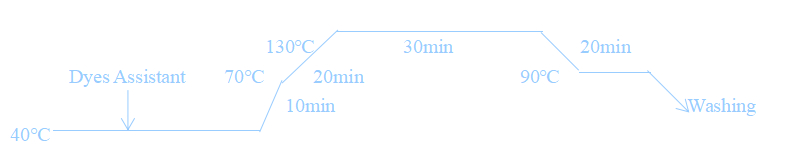

1.2.1 Common dyeing

1.2.2 Special dyeing

2. Padding

2.1 Recipe of padding liquor

Dyes.........................................................x

Levelling agent....................................10g

Na3PO4..................................................100g

Adding water to .................................50L

2.2 Procedure

Padding( liquor pick-up: 80%, Temp.: 60℃ )→Steaming ( Temp.: 100-103℃, Time:1-4min )→

Washing→Fixing→Washing→Drying

Navigation

Navigation

Contact Us

Tel: +86 22 2782 4571

Mob.: +86 152 2234 5826

Fax: +86 22 2782 7649

E-mail: sales@tianjinleading.com

WhatsApp: +86 152 2234 5826

WeChat: +86 152 2234 5826

Add.:2104 Jiali Center, No 73, Weijin Rd, Tianjin, China